Special Designs

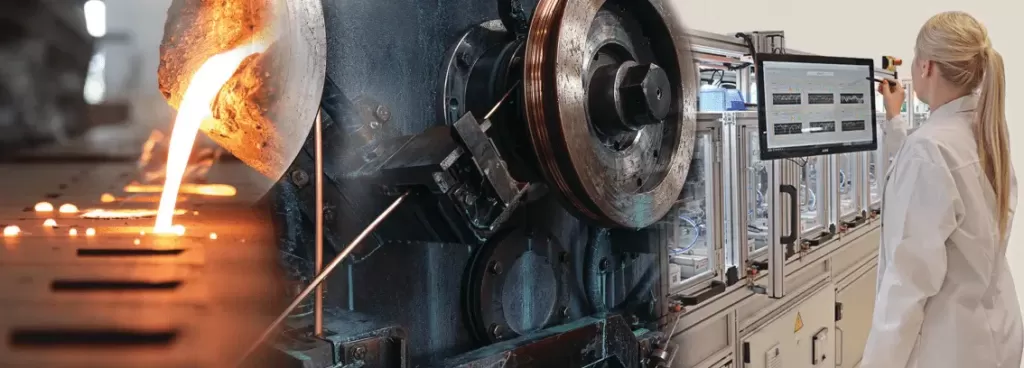

Encoder Technology goes beyond standard offerings by providing bespoke designs.

This means we can create custom-tailored encoders specifically for your unique needs and specialized requirements. Whether you have a complex application with unconventional demands or require features unavailable in mass-produced models, our team of experts can design and build an encoder that perfectly fits the bill.

So, if you’re looking for an encoder solution that doesn’t compromise functionality or performance, don’t hesitate to contact Encoder Technology directly.

We’re ready to discuss your project and translate your vision into a tangible solution that exceeds expectations and the demands of the project.

For special design requests, please contact our sales team.