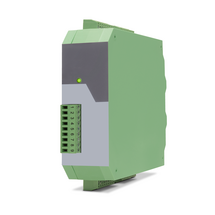

Features

- MC700 is a universal motion controller for 1 to 4 axis, programmable for multiple motion applications by simple download of the corresponding function firmware

- With the use of Matona's CT701 firmware, this unit provides excellent solutions with all kinds of guillotine cutters and rotary eccentric shears needing a cosine-compensated speed profile during the penetration of the tool

- Extremely smooth motion to protect mechanical solution, by self-optimizing polynomial speed transitions

- High cutting accuracy, even during line acceleration and at high speeds

- Programmable cosine-compensated speed profile

- Special torque control features to master the impact load when cutting hard materials like stainless steel etc.

- Special profile features to avoid deadlock between tool and material

- Embedded virtual master axis (selectable)

- Black-box unit for cabinet mounting

- Remote control and communication facilities via external operator terminal, serial PC communication, PROFIBUS or optional via CANBUS (MC700/CI) etc.